The production of ethanol from starch or sugar-based crops is among man’s earliest ventures into value-added agriculture-based processing.

Henry Ford and Alexander Graham Bell were among the first to recognize that the plentiful sugars found in plants could be easily and inexpensively converted into clean-burning, renewable alcohol fuels.

While the concept is the same today as it was then, the ethanol industry has come a long way since those days. Today, sophisticated renewable fuel refineries operate much like a chemical refinery, able to produce multiple renewable fuels and products. Using state-of-the-art technologies, ethanol biorefineries convert grains, beverage and food waste, cellulosic biomass and other products called feedstocks into high-efficiency ethanol.

Over 90 percent of the grain ethanol produced today comes from the dry milling process, with the remaining coming from wet mills. The main difference between the two is in the initial treatment of the grain.

Dry Mill Ethanol Process

In dry milling, the entire grain kernel is first ground into “meal,” then slurried with water to form a “mash.”

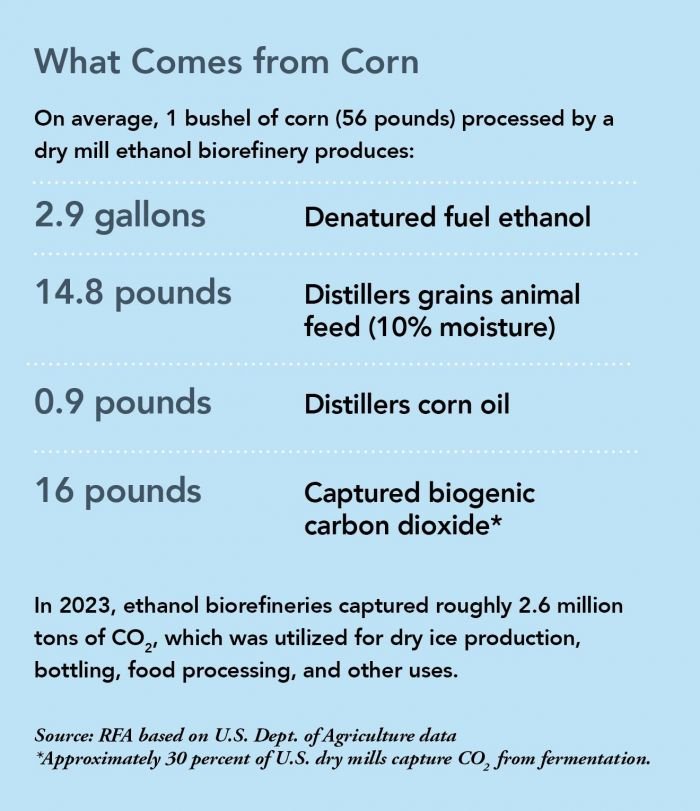

Enzymes are added to the mash to convert starch to sugar. The mash is cooked, then cooled and transferred to fermenters. Yeast is added and the conversion of sugar to alcohol begins. After fermentation, the resulting “beer” is separated from the remaining “stillage.” The ethanol is then distilled and dehydrated, then blended with about 2% denaturant (such as gasoline) to render it undrinkable. It is then ready for shipment. The stillage is sent through a centrifuge that separates the solids from the solubles. These co-products eventually become distillers grains, as well as corn distillers oil. For more information on co-products and current production, visit our co-products page.

Wet Mill Ethanol Process

In wet milling, the grain is first separated into its basic components through soaking.

After steeping, the slurry is processed through grinders to separate the corn germ. The remaining fiber, gluten and starch components are further segregated. The gluten component (protein) is filtered and dried to produce animal feed. The remaining starch can then be fermented into ethanol, using a process similar to the dry mill process.