Sophisticated grain ethanol production facilities have been utilizing engineering and design enhancements, new process technologies, automation upgrades, and other advances to make remarkable gains in efficiency to extract more out of each bushel of corn.

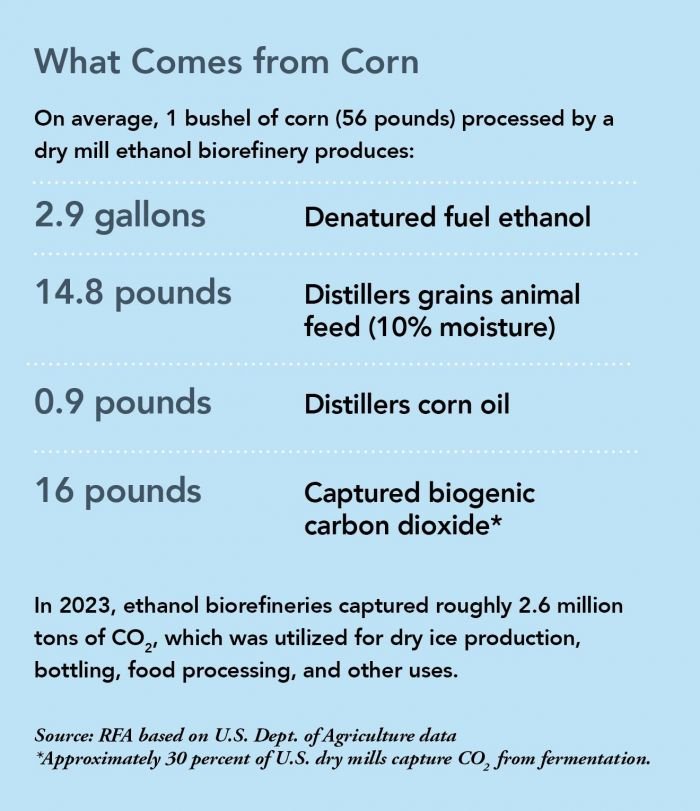

U.S. ethanol biorefiners produce distillers grains, gluten feed and gluten meal. These bio-products are valuable corn and soybean meal substitutes in rations used around the world to feed beef and dairy cows, pigs, chickens, turkeys, fish and other animals. In addition, ethanol plants extract corn distillers oil – an important market underpinning the production of biodiesel and animal feed.

Now fully under the regulatory oversight of the U.S. Food & Drug Administration, ethanol plants are required to comply with preventive controls requirements as mandated by the Food Safety Modernization Act (FSMA).

This federal rule requires covered facilities to follow current good manufacturing practices for animal food production and have a written food safety plan that includes an analysis of hazards and risk-based controls. These preventive controls provide a formal assurance to buyers around the world that American ethanol co-products continue to be safe feed ingredients.

Biogenic carbon dioxide (CO₂) is captured by about a quarter of U.S. ethanol producers and is used for everything from beverage carbonization and meat processing to wastewater treatment and dry ice production. In 2021, RFA's member producers unanimously pledged to produce ethanol with net-zero carbon emissions, on average, by 2050 or sooner. Lowering carbon emissions can be achieved with workable improvements both on the farm and at the biorefinery, especially with renewable energy use and carbon capture and sequestration.

Use The Form Below to Start Your Download

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse varius enim in eros elementum tristique. Duis cursus, mi quis viverra ornare. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse varius enim in eros elementum tristique. Duis cursus, mi quis viverra ornare

Related RFA Publications

Resources & Helpful Links

RFA/NCGA/AFIA’s Distillers Grains Testing Guidelines

ISU’s Mycotoxins in the Grain Market

USGC’s DDGS User Handbook

USGC’s Best Management Practices to Avoid Pest Contamination of DDGS

Additional Reports and Studies

American Feed Industry Association (AFIA)

Association of American Feed Control Officials (AAFCO)

FDA FSMA Technical Assistance Network (TAN)

FDA Center for Veterinary Medicine (CVM)

Food Safety Preventive Controls Alliance (FSPCA)

Distillers Grains Technology Council (DGTC)

National Grain and Feed Association (NGFA)

U.S. Grains Council (USGC)

USDA Federal Grain Inspection Service (FGIS)